|

The Exponential Engine

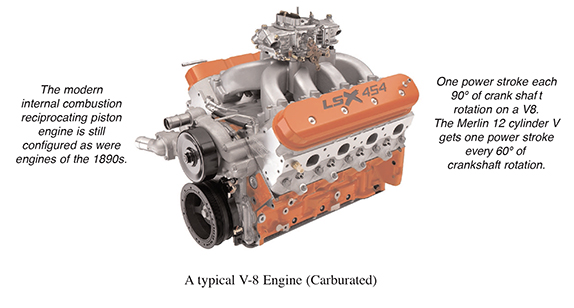

A new paradigm has been created for internal combustion reciprocating engines. The Otto, Diesel and Carnot cycles have served us well for many years and while there have been many changes to the original internal combustion engine the concept of the very first engines of the 1860s can be seen in today's engines. Take a walk through an historical museum chronicling the developmental history of engines and my point will be made. Such a place is the Hiller Aviation Museum adjacent to the San Carlos Airport in San Carlos, California. Start at the 1903 Charles Taylor engine and work your way through the years, engine by engine, until you reach the 1955 Pratt & Whitney R4360-CB2, a 28 cylinder 3500 h.p. engine. Yes, 1955 is not today but if the exhibit did go to today the similarity would still be there. What the world's engineers have done is take a good idea and continue to improve on its implementation without changing the basic concept. The ExponentialTM Engine changes that basic construction concept dramatically while retaining many proven design features.

Today's reciprocating engines are computer controlled and can vary fuel mixtures, valve timing, ignition timing and just about anything else you want. Most new engines use computers to sense the environment and engine conditions; using that real time data the computer will adjust the engine for optimum operation. All these improvements are wonderful and they optimize performance, however the engine is still 90% the same as it was 150+ years ago. When change has occurred it has been a major change and that created a new kind of engine. The jet engine or turbine type, whether using exhaust blast as a jet or turning a propeller as a turboprop, are examples of major changes. The diesel engine (a child of the ignition reciprocating engine), as well as the failed Wankel and Bourke engines were all attempted departures from the original reciprocating ignition engines basic design. Today only the diesel remains. Many of the engine modification attempts contained valuable advances, which in most cases never matured. The Bourke engine almost became a new standard and the concepts that Bourke presented can be found in racing engines of today as well as in the ExponentialTM Engine. We believe the ExponentialTM Engine will become the worlds standard for reciprocating internal combustion engines.

The ExponentialTM Engine was originally created for use in aircraft. The engine concept was presented to DARPA (Defense Advanced Research Projects Agency) in the late 1900s and was passed over as being too radical a change. Though rejected, the creator of the engine continued the pursuit of this new concept with the intent of leap-frogging technology as opposed to making small incremental changes. So what does the ExponentialTM Engine present that would qualify for a new paradigm? Remember that reciprocating aircraft engines were the target of this project and power to weight ratios are the major concern when building aircraft engines. The ExponentialTM Engine can produce a minimum of four times the output power when compared to a modern day reciprocating piston aircraft engine of equal weight and displacement. The four times power output is just the beginning, recognize that a 16 times the power of today's newest technology for a 12% increase in weight and for the same displacement is achievable. The ExponentialTM Engine is not only lightweight, it is also compact resulting in a small size with a low drag frontal area, an important feature in aircraft.

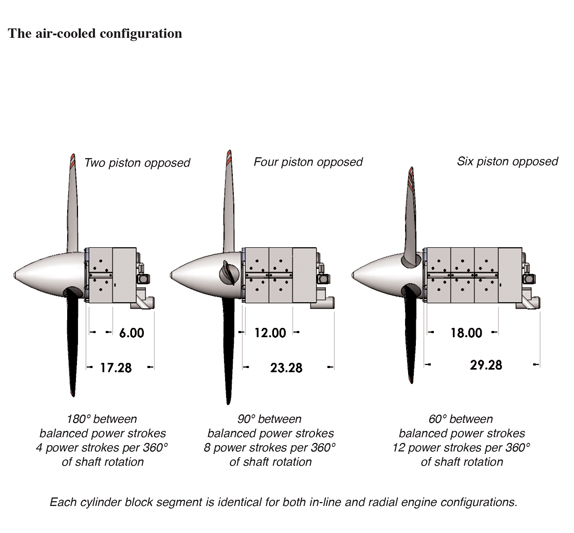

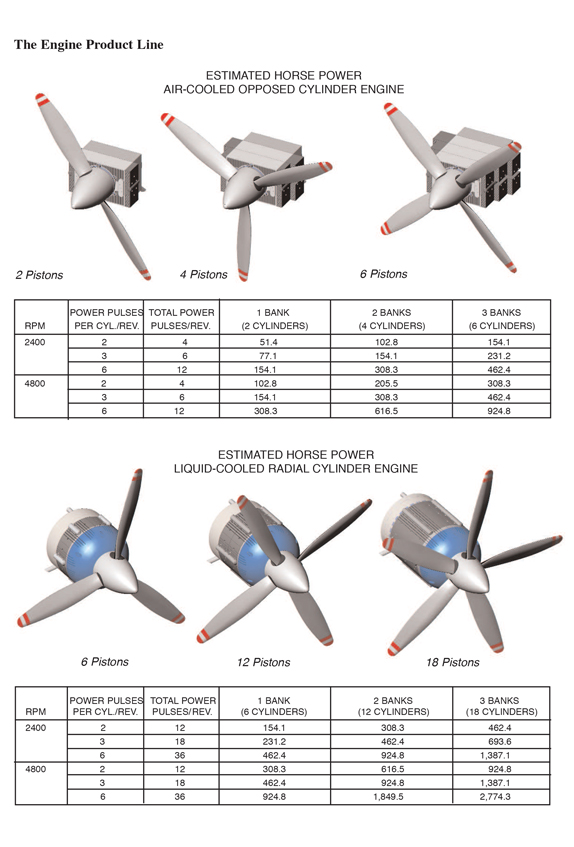

The Proof OK, so you want to know how can the ExponentialTM Engine out perform all the engines of the world. Well, we can't tell you how we did it because of our pursuit of patents, but we can tell you what we did. In simple terms the power output of an engine is directly related to the rate at which it consumes fuel if we hold all other parameters equal. One way to burn more fuel is to increase the number of power pulses per unit of time, rpm. This is why racing engines run at 14,000 rpm and higher while the engines of the 1800s and early 1900s ran at only 1000 rpm. There is another way to burn more fuel and it is to increase the size of the engine. Still another is to increase the number of pistons. All these things you already know and all these techniques have been used. What the ExponentialTM Engine design achieves is: it keeps the engine small in size, it keeps the number of pistons to common numbers like 2, 4, 6, 8, 12, etc., and it permits running the engine at a reasonable speed in the low thousands of rpm. The major difference is that the ExponentialTM Engine gets a minimum of two power stokes from each piston for each 360° of crankshaft rotation. When you compare power pulses achieved by the ExponentialTM Engine to the standard aircraft engine or typical automobile engine both of which get one power pulse per piston for each 720° of crankshaft rotation, you can immediately see that the ExponentialTM Engine will deliver a minimum of 300% more power holding all other factors constant [standard engine output power times four (4 x)]. This would be true at any rpm because there are always an additional three power strokes for the ExponentialTM Engine compared to the one power stroke of the conventional four stroke engine which requires two revolutions (720°) of crankshaft rotation for one power stroke. Now don't forget that the original concept for the ExponentialTM Engine was intended to improve on reciprocating aircraft engines and reciprocating aircraft engines turn propellers. Propellers like to turn at speeds around 2400 rpm; therefore the engine was designed for that rpm. Should you want higher or lower shaft speeds, provision has been made for step-up or step-down gearing. Also know that the engine is not limited to 2400 rpm, any rpm can be selected within the design limits up to 6,000 rpm and that is exclusive of gearing. Earlier in this article we stated that the power extracted from an engine is directly related to the rate at which fuel is burned. That statement makes the assumption that all the fuel is burned. In actuality the fuel in an engine cylinder is seldom completely burned. The higher the speed of the engine, the shorter the time in which the fuel can burn and consequently the poorer the fuel efficiency of the engine; the Bourke engine with its Scotch Yoke taught us that in 1942. If you are a pilot flying a reciprocating engine aircraft you do an ignition system check prior to departing and see the rpm of your engine drop by 100+ rpm as you switch from dual ignition systems (2 spark plugs firing at the same time in each cylinder) to one ignition system (1 spark plug firing in each cylinder). The fuel burn is slower with one spark plug and therefore the power achieved for the same fuel charge is lower. This we know to be true from millions of such tests which happen each and every day. We also know that the dual ignition in aircraft is there for safety reasons not for fuel economy reasons. It is obvious that two spark plugs in a single cylinder increase fuel burn rate for the same time increment and that produces more power because it burns more of the fuel and at a higher rate. The same result of higher power can be achieved by a longer burn time increment design (Bourke engine with Scotch Yoke), which permits a much more complete burn and the extraction of more power from the same fuel charge.

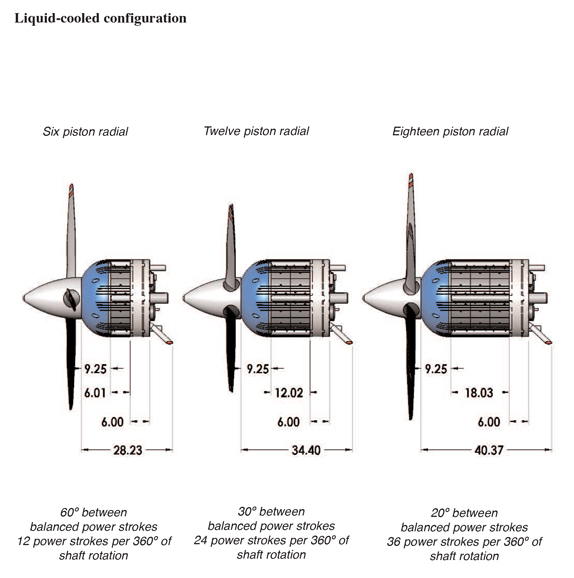

There is an additional method for increasing the fuel burn rate without changing the fuel. Both fuel economy improvement and reduced emission contaminents are achieved in diesel engines by the introduction of disassociated water. Disassociated water is the term used to describe a process which breaks water into it's components of hydrogen and oxygen gases. In this case the gases are introduced into the cylinder in the same proportion as their original water form. The hydrogen burn flame front rate is 400 times faster than the diesel fuel burn flame front rate and leads to a much more complete fuel burn. This system is approved for use in California and can also be used on the ExponentialTM Engine. The ExponentialTM Engine provides both dual ignition and increased piston dwell time during combustion for complete fuel burn to achieve maximum power extraction. In addition the engine can be equipped with either an electronic ignition or a laser ignition. The laser ignition can provide multiple ignition flash points and eliminates electromagnetic interference with communication and navigation gear. The electronic ignition provides high intensity spark from a dual spark plug system which can use standard spark plugs and the entire system is contained beneath EMI shielding cover plates to eliminate RFI. Operating Cycle Now let's talk about the running cycle which defines an engine. The Otto and Diesel cycles require four strokes; intake, compression, power and exhaust. This is done in two rotations of the crankshaft or 720° of crankshaft rotation. We refer to this as a "four stroke cycle" engine. However, there is an engine, which accomplishes these four functions (intake, compression, power, exhaust,) in only two strokes or 360° of crankshaft rotation. That engine is referred to as a "two stroke cycle" engine. One can see immediately that for the same rpm you will get two times the number of power stokes and therefore twice the power, all other factors being equal. In the real world the factors affecting performance are not equal and there are differences in these engines which favor the four stroke cycle engine. The two stroke cycle engine was designed with a requirement of adding oil to its fuel in order to lubricate the engine. The hassle of mixing fuel with oil and environmental emission restrictions limit its use. Small and lightweight uses such as model airplanes, lawn equipment and scooters are common applications for the 2-stroke, but the 2-stroke cycle engine is seldom found in cars, trucks or aircraft. When we compare The ExponentialTM Engine to the two stroke and four stroke cycle engines we find that the ExponentialTM Engine can be configured to run in either of these two different modes of operation but neither of today's current engines compares in performance to the standard ExponentialTM Engine mode. The most common mode used today and the mode we will use as a comparison standard is the four-stroke cycle which is standard among aircraft and automobile engines. The second mode of operation which can also be used for the ExponentialTM Engine is a two stroke cycle, however the ExponentialTM Engine two stroke cycle is very different than the standard and common two stroke cycle engine we have discussed. The standard two-stroke cycle engine replaces poppet valves with valve ports which do not move. While eliminating parts is always good, the need for oil in the fuel and the restrictions imposed by the design spelled the end for this type of engine for large power requirements. However, in England during and after WWII ended, an engine was created for aircraft which used moving sleeves to replace always open valve ports or pop-it valves. While this engine (called the Centaurus) achieved high power to weight ratios, it was used for only a short time and eventually the concept was abandoned. The ExponentialTM Engine uses standard poppet valves which are a proven technology for both our two stroke and four stroke configurations and there is no requirement for oil in the fuel. The ExponentialTM Engine two-stroke cycle is: intake, burn, power, exhaust; only power and exhaust are actual piston moving strokes and therefore there are only two strokes. The intake and compression strokes are gone and a burn phase has been added. The variable configuration attributes of the ExponentialTM Engine permits each version of this engine to be configured for two to six power strokes per cylinder per revolution or a maximum of 36 power strokes per 360° of crankshaft rotation per bank of six cylinders. Stated differently, it is equal to a power stroke every twenty degrees of shaft rotation. This is not an error in our math although one would expect the answer to be 10°. Because opposed cylinders fire simultaneously, two balanced power strokes occur at the same point in time and therefore the increment is actually 20°.

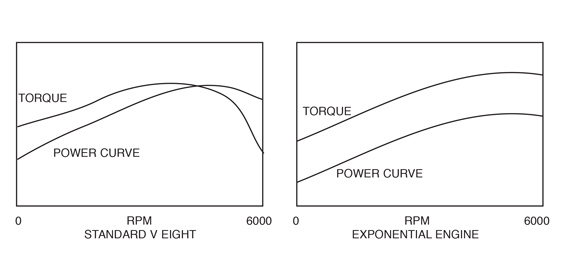

Additional Benefits We have discussed the primary improvements provided in the ExponentialTM Engine, that of an increase in power pulses per revolution. While this is certainly a major breakthrough in technology it is only one of many. When we examine torque curves for engines we generally see an arc which drops off sharply as speed increases, we also see the power curve descend sharply at higher rpm. The unique design of the ExponentialTM Engine delivers a near flat torque curve and a near flat curve for power. Even more of a departure from the conventional engine is the ability to have different stroke lengths for a single piston. Yes, we mean the power stroke can be longer than the exhaust stroke for the same piston. The ExponentialTM Engine also provides sleeveless cylinder walls, carbon impregnated compression rings, sealed and vented piston "blow-by," extended oil life to a minimum of three times current recommendations, possibly oiless running, constant and increased power at altitude without supercharging, altitude normalization not cylinder pressure normalization, fuel vaporization system, vaporized water injection, disassociated water injection and still more to come.

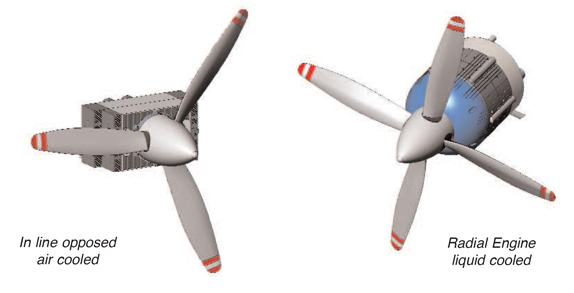

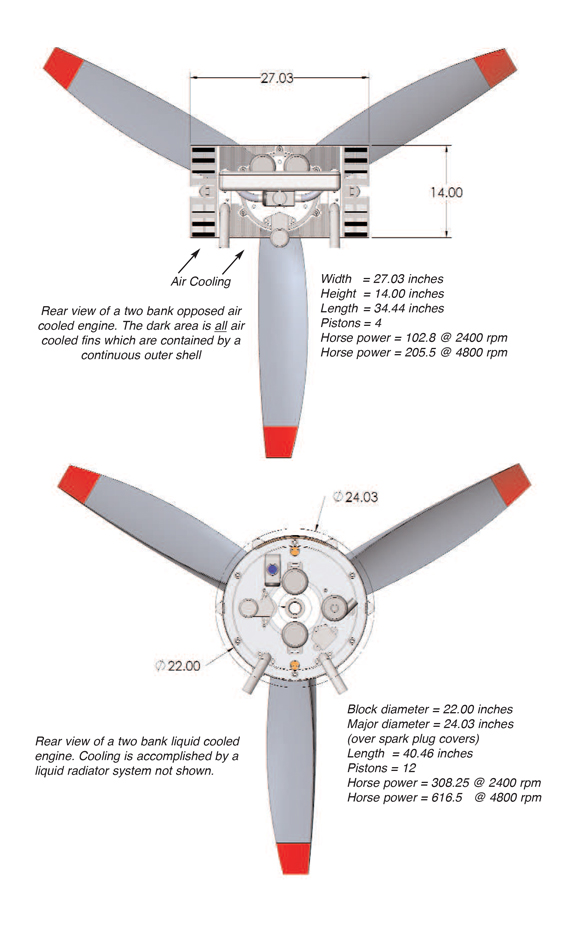

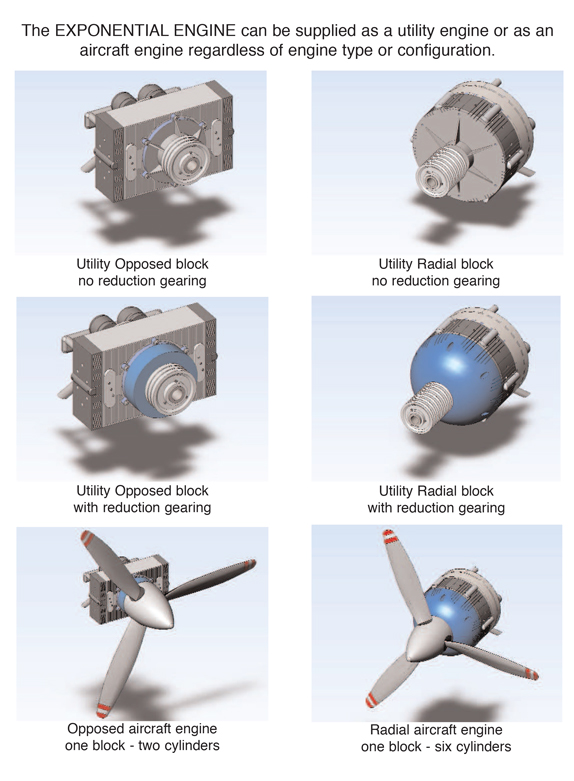

I hope I have whet your appetite for more information about the ExponentialTM Engine. Our original intent was to replace all current air-cooled reciprocating aircraft engines with a revolutionary engine of lightweight and high power output. This goal has been achieved in theory by the air-cooled version of the ExponentialTM Engine. The liquid cooled version of the ExponentialTM Engine also provides much higher power to weight ratios than conventional engines, however, the radial version requires a radiator system which limits retrofitting to many existing aircraft. When an aircraft is designed with the liquid cooled radial ExponentialTM Engine in mind all the benefits which are designed into the engine make the ExponentialTM Engine radial the best choice. An additional goal of this project was the use of alternate fuels such as diesel fuel, CNG (compressed natural gas), plus Jet A, A1 and B. The liquid-cooled ExponentialTM Engine is intended for both airborne and non-aircraft implementation and can produce much more power per pound of weight (including the liquid cooling system) than the air-cooled version. The liquid cooled engine can find application in appropriately designed aircraft and immediate use in land and sea vehicles such as cars, trucks and boats plus non-mobile applications like auxiliary power stations, pumping stations and numerous other uses. Don't forget those race car engine uses! See you at the races: air, land and sea. Please review some of the engine configurations and applications which follow.

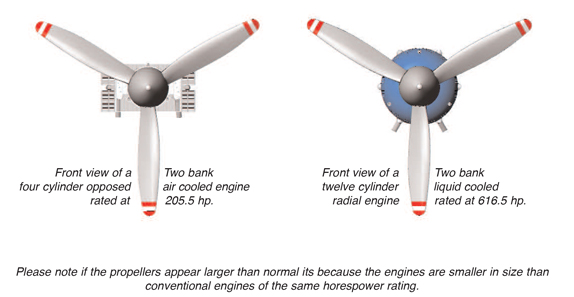

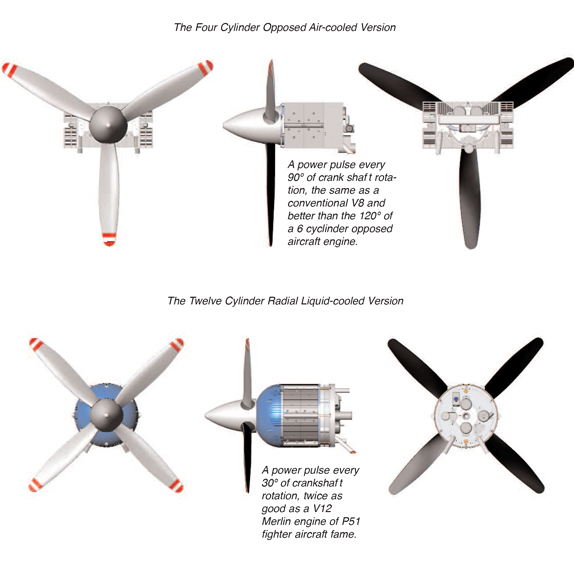

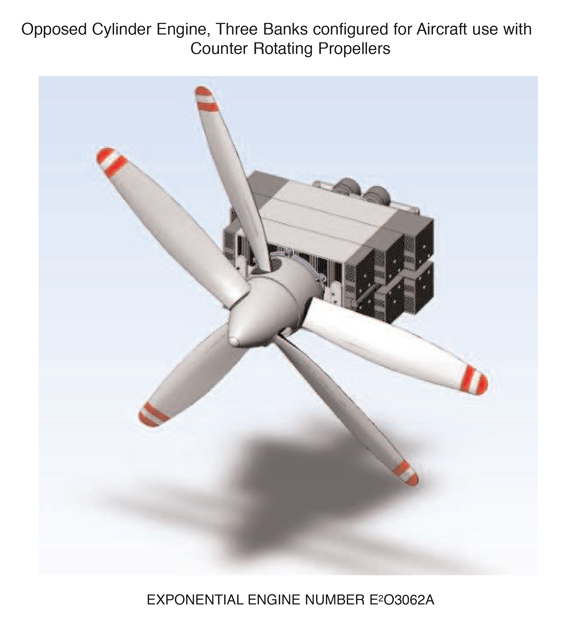

A six (6) cylinder opposed inline air cooled engine using dual shaft direct drive counter rotating propellers. Horse power rating range is from 154 to 462. This engine can be fitted with a fixed or variable pitch propeller. The variable pitch type propeller which allows full feathering can be utilized when shutting down one portion of the engine while in flight thereby reducing fuel consumption. Counter rotating engines (not just propellers) reduce or eliminate full power roll torque at take off. This engine can be equipped with an Oxygenation System for high altitude operation and water vapor injection is also available. No engine cowling is required or desired.

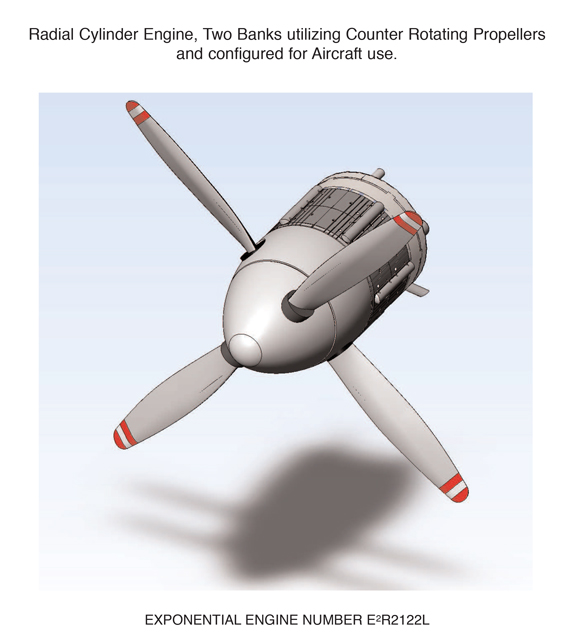

A twelve (12) cylinder radial liquid cooled engine using dual shaft direct drive counter rotating propellers. Horse power rating range is from 154 to 925. This engine can be fitted with a fixed or variable pitch propeller. The variable pitch type propeller which allows full feathering can be utilized when shutting down one portion of the engine while in flight thereby reducing fuel consumption. Counter rotating engines (not just propellers) reduce or eliminate full power roll torque at take off. This engine can be equipped with an Oxygenation System for high altitude operation and water vapor injection is also available. No engine cowling is required or desired. We are now moving to production with both these engine designs. The ExponentialTM Engine design is becoming a real piece of hardware as you read this article. Should you desire more information on our engines or just want to stay informed of our progress, you can visit our website at www.exponentialengine.com. Respectfully submitted, Frank J. Ardezzone |

||